Welcome to this informative article on Understanding Regulation 411.3 1.2 BS 7671! In this comprehensive overview, we will delve into the intricacies of this regulation and provide you with a clear understanding of its key concepts. So, let’s jump right in!

Understanding Extraneous Conductive Parts: A Practical Guide for Identification and Determination

Understanding Extraneous Conductive Parts: A Practical Guide for Identification and Determination

📋 Content in this article

When it comes to electrical installations, it is crucial to understand the concept of extraneous conductive parts and their impact on safety. In this comprehensive guide, we will explore the key aspects of extraneous conductive parts and provide practical tips for their identification and determination. Let’s dive in!

1. What are Extraneous Conductive Parts?

Extraneous conductive parts refer to any conductive object or structure that is not part of the electrical installation but can become electrically charged due to faults or other abnormal conditions. These parts can pose serious risks, such as electric shock or fire hazards, if not properly identified and addressed.

2. Common Examples of Extraneous Conductive Parts

Extraneous conductive parts can take various forms and are often found in both domestic and commercial settings. Here are some common examples:

3. Identification of Extraneous Conductive Parts

To ensure electrical safety, it is essential to accurately identify extraneous conductive parts. Here are some steps you can take:

4. Determination of Protective Measures

Once extraneous conductive parts are identified, appropriate protective measures must be implemented. The determination of these measures depends on various factors, including the nature of the installation and the level of risk involved. Here are some considerations:

5. Seeking Professional Assistance

Identifying and determining extraneous conductive parts can be complex, especially in larger or more intricate installations. It is highly recommended to seek professional assistance from qualified electricians or electrical engineers who have expertise in this area. They can provide accurate assessments, guidance, and ensure compliance with relevant regulations.

In conclusion, understanding extraneous conductive parts is crucial for maintaining electrical safety in any installation. By accurately identifying these parts and implementing appropriate protective measures, the risk of electric shock or fire hazards can be significantly reduced. When in doubt, don’t hesitate to consult professionals who can provide the necessary expertise for a safe electrical environment. Stay informed and stay safe!

Understanding the Importance of the Main Protective Bonding Conductor in Electrical Systems

Understanding Regulation 411.3 1.2 BS 7671: A Comprehensive Overview

Regulation 411.3 1.2 of BS 7671, also known as the Wiring Regulations, is an important standard that establishes guidelines for electrical installations in the United Kingdom. This regulation focuses on the main protective bonding conductor and its crucial role in electrical systems.

What is the main protective bonding conductor?

The main protective bonding conductor, often referred to as the CPC (Circuit Protective Conductor) or the earth wire, is an essential component of electrical installations. Its purpose is to provide a low impedance path for fault currents to flow safely to the earth in the event of a fault.

Why is the main protective bonding conductor important?

The main protective bonding conductor plays a critical role in protecting individuals and property from electrical hazards. It helps to prevent electric shock by ensuring that any fault current is quickly diverted away from exposed conductive parts, such as metal casings or appliances.

Requirements of Regulation 411.3 1.2

Regulation 411.3 1.2 of BS 7671 sets out specific requirements for the main protective bonding conductor in electrical systems. These requirements include:

1. Size and material: The main protective bonding conductor should have adequate cross-sectional area and be made of a suitable material, such as copper or aluminum.

2. Routing and termination: The main protective bonding conductor should be routed and terminated in accordance with industry best practices to ensure proper electrical continuity and effective fault current diversion.

3. Connections: The main protective bonding conductor should be securely connected to exposed conductive parts, such as metal pipes, building structures, and electrical equipment, to maintain reliable equipotential bonding.

4. Testing and verification: It is essential to regularly test and verify the effectiveness of the main protective bonding conductor to ensure its proper functioning. Periodic inspection and testing help identify any faults or deficiencies that may compromise safety.

Importance of Compliance

Compliance with Regulation 411.3 1.2 is crucial for electrical safety. By adhering to these requirements, electrical installations can minimize the risk of electric shock, fire, and other hazards. Non-compliance may not only endanger lives but also result in legal consequences and liability for those responsible for the installation.

Is Earth Bonding a Legal Requirement: What You Need to Know

Understanding Regulation 411.3 1.2 BS 7671: A Comprehensive Overview

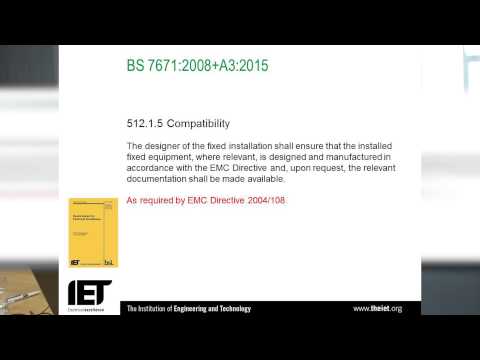

When it comes to electrical installations, safety is of paramount importance. Regulatory bodies, such as the International Electrotechnical Commission (IEC), have established standards to ensure the safe operation of electrical systems. In the United Kingdom, the British Standards Institution (BSI) has developed a set of regulations known as BS 7671, which outlines the requirements for electrical installations.

One key aspect of BS 7671 is Regulation 411.3 1.2, which pertains to ‘earth bonding’. Earth bonding, also referred to as ‘earthing’ or ‘grounding’, involves connecting metal parts of an electrical installation to the earth in order to prevent electric shock and reduce the risk of fire.

Is Earth Bonding a Legal Requirement?

The short answer is yes. Regulation 411.3 1.2 of BS 7671 states that earth bonding is a legal requirement for electrical installations in the United Kingdom. This means that anyone involved in designing, installing, or maintaining electrical systems must comply with this regulation to ensure the safety of individuals and property.

What Does Earth Bonding Involve?

Earth bonding involves connecting conductive metal parts, such as electrical enclosures, conduits, and equipment frames, to the earth using low-impedance conductors. These conductors create a path for electrical faults to safely dissipate into the ground, preventing the build-up of dangerous voltages.

The specific requirements for earth bonding depend on various factors, including the type of installation, the nature of the equipment, and the location. However, some common elements include:

Why is Earth Bonding Important?

The main purpose of earth bonding is to ensure electrical safety. Here are some key reasons why earth bonding is important:

1. Protection against electric shock: By connecting metal parts to the earth, any fault currents are directed away from individuals, reducing the risk of electric shock.

2. Prevention of fire hazards: Earth bonding helps prevent the build-up of dangerous voltages, which can lead to electrical arcing and potentially cause fires.

3. Compliance with regulations: Meeting the requirements of BS 7671 and Regulation 411.3 1.2 is essential for ensuring legal compliance and avoiding potential penalties or liability issues.

4. Insurance and certification: Proper earth bonding is often a requirement for obtaining insurance coverage and certification for electrical installations.

Understanding Regulation 411.3 1.2 BS 7671: A Comprehensive Overview

In today’s rapidly changing legal landscape, it is essential for professionals to stay up-to-date with the latest regulations and standards relevant to their field. This is particularly true for those working in the electrical industry, where adherence to safety standards is paramount.

One such regulation that demands our attention is Regulation 411.3 1.2 of the BS 7671, which sets out requirements for the protection against electric shock in electrical installations. Understanding and complying with this regulation is crucial for anyone involved in the design, installation, inspection, testing, or maintenance of electrical systems.

Regulation 411.3 1.2 BS 7671 focuses on the provision of additional protection against electric shock in certain specific locations within electrical installations. It requires the use of additional protection measures such as Residual Current Devices (RCDs) or other suitable devices to reduce the risk of electric shock.

To comply with this regulation, electrical professionals must have a solid understanding of its key provisions. Some important aspects include:

1. Specific locations: Regulation 411.3 1.2 applies to specific areas where a higher degree of protection against electric shock is necessary. These areas include bathrooms, swimming pools, construction sites, and agricultural and horticultural premises, among others.

2. Application of additional protection: The regulation mandates that additional protection measures be applied to circuits supplying these specific locations. This typically involves the installation of an RCD or other suitable protective device to detect any imbalance in current flow and quickly disconnect the circuit if necessary.

3. Risk assessment: It is essential to conduct a thorough risk assessment to identify the specific locations within an electrical system where additional protection measures are required. This assessment should consider factors such as the proximity of water sources, the nature of the activities taking place, and the potential for electrical faults.

Staying up-to-date with Regulation 411.3 1.2 BS 7671 is crucial for several reasons. Firstly, non-compliance can lead to serious safety hazards, including the risk of electric shock and potential harm to individuals. Secondly, failure to comply with this regulation could result in legal consequences, including fines and other penalties. Lastly, keeping abreast of changes and updates to the regulation ensures that professionals are providing the highest level of safety and protection to their clients and the general public.

It is important to note that this article provides a general overview of Regulation 411.3 1.2 BS 7671 and should not be considered as legal advice or an exhaustive guide. It is always advisable to verify and contrast the content of this article with the relevant legal sources to ensure full compliance with current regulations.

In conclusion, understanding and complying with Regulation 411.3 1.2 BS 7671 is of utmost importance for electrical professionals. It is essential to stay informed about the latest changes and updates to this regulation to ensure the safety of individuals and maintain legal compliance.